|

Chapter 2: Homemade Motor Couplers and Errors to Avoid

Attaching a motor to a wheel can be more difficult than you might think. This chapter

presents an alternate technique (step-by-step instructions follow in Chapters 3 and 4)

from the telescoping-tubing technique presented in the first book.

This chapter contains photographs of clear (acrylic) couplers to show off the inner

details. This is especially useful on couplers that have common mistakes. Following each

problematic coupler is a photograph of how an attached wheel would then rotate.

Chapter 3: Making a Fixture and Drilling Solid Rods

One of the most frustrating machining problems is trying to drill a hole exactly in the

center of a round piece, such as a rod. This chapter describes one technique that provides

excellent results.

This chapter includes a checklist for selecting a drill for machining aluminum or plastic.

An explanation is provided for why you should create a fixture and the benefits of an X-Y

table (found on milling machines but can be added to a drill press).

Chapter 4: Tapping Holes and Selecting Setscrews

This chapter describes three differed tap styles for making threads in holes (so that a

machine screw can be inserted). In particular, this chapter explains why you might choose

one tap style over another.

The solid-rod coupler project started in Chapter 2 is finished here.

Chapter 5: A Motor Inside of a Wheel

Many of the best sumo robots have wide wheels with motors installed inside of them. This

places the largest mass (the motors) low to the ground to make it difficult for an

opponent to tip the robot over. This chapter describes one method for building motors into

wheel hubs, while still permitting them to be easily removed for servicing.

This chapter has a lot of interesting machining tips (mating parts, when to use an

unthreaded hole, Silver & Deming drills). In fact, this chapter shows how to make your

own wheels, if you so desire.

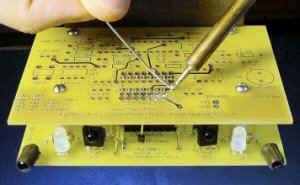

Chapter 6: Standards for Electronic Experiments

This is a transitional chapter which tells you how to read the schematics in the book,

provides suggestions on bench power supplies, and debates the inevitable changeover to

surface-mount technology. (By the way, all of modules in this book are based on

through-hole parts, which are easier for the hobbyist to use.)

Chapter 7: Linear Voltage-Regulated Power Supply

Nearly every robot needs a regulated supply of power. This chapter begins with a really

simple +5V power supply circuit based on the classic 7805. The circuit is improved with

reverse-battery protection via a diode, followed by a more voltage-efficient solution that

also only requires one component.

A few pin-compatible low-dropout versions of the 7805 are swapped into the power supply

circuit and the performance is then compared.

Chapter 8: Robot Power Supply Improvements

Unlike some other electronic devices, robots can place extra strain on their power

supplies. This chapter beefs up the power-supply circuit presented in Chapter 7, by adding

bulk capacitors, regulated voltage protection (zener diode), overcurrent protection

(resettable fuse or PPTC), rapid turn off (capacitor discharging through a high-wattage

resistor), and noise reduction (short leads and voodoo capacitors). You may choose to

implement none, some, or all of these techniques on your next robot.

This chapter looks at capacitors in great detail (Chapter 11 also includes some tips). In

particular, proper working voltage (WV), placement, and sizing are discussed to provide

the longest practical life span.

Chapter 9: Motor Drivers - Bipolar

This chapter begins by demonstrating the four modes (clockwise, counterclockwise, coast,

and brake) available in a standard DC motor. Motor driver circuits are built step-by-step

from the most simple (single transistor) all the way up to the classic H-bridge.

This chapter mainly focuses on bipolar transistors, such as the 2222 and 2907. The

benefits of the popular 4424 and 4427 interface chips are described when the chapter

branches into interfacing the motor drivers to logic chips and microcontrollers.

Chapter 10: Power MOSFET Motor Drivers

The MOSFET Motor Driver chapter begins by recreating the bipolar motor driver circuits

from Chapter 9, but with power MOSFETs instead. This covers pull-up and pull-down

resistors, shoot through, and body diodes versus discrete Schottky diodes.

This chapter includes the key criteria for selecting a MOSFET. A lot of attention is

focused on resistance, including paralleling MOSFETs for improved performance.

(Steady-state Parallel MOSFETs self-balance due to their thermal coefficient, as opposed

to bipolar transistors that can experience thermal runaway. Find out what that means in

this chapter.)

The chapter concludes by describing some popular motor driver chips, which are more

compact and feature rich than motor drivers you can build by hand. The motor drivers are

then compared in head-to-head performance testing for powering miniature DC motors.

How good is the MC33887 compared to a discrete 2222/2907 H-bridge, 4427, or discrete

HEXFET H-bridge? What's the deal with the SN754410?

Chapter 11: Infrared Detector

The Panasonic PNA4602M 38 kHz infrared detector is very popular in the robotics community,

especially in sumo robots. The responsiveness of the detector is analyzed along with a

simple method of testing it (and any other 38 kHz detector, like those made by Sharp).

This chapter steps you through making a complete dual emitter, detector, and bicolor

indicator circuit based around a common logic chip. You can use this stand-alone detector

on your robot for detecting walls, obstacles, or even opponents.

Selection criteria for infrared emitters / infrared LEDs are listed, along with selection

criteria for timing and noise-reduction capacitors.

Chapter 12: Fine Tuning the Reflector Detector

This chapter finishes up the infrared reflector detection circuit. The chapter begins with

several techniques for tuning the 38 kilohertz square wave: by hand, using a multimeter

with a frequency mode, and with an oscilloscope.

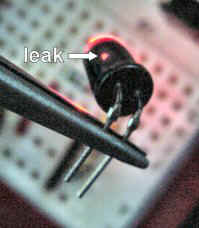

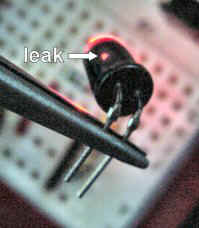

Four alternatives are provided for avoiding side leakage in infrared emitters. Limitations

of infrared detection are revealed, including the effects of shapes, ambient lighting, and

materials.

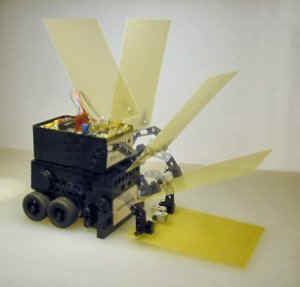

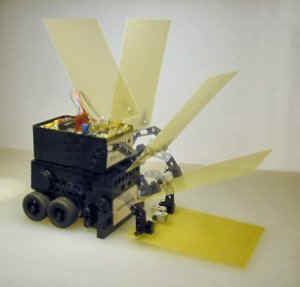

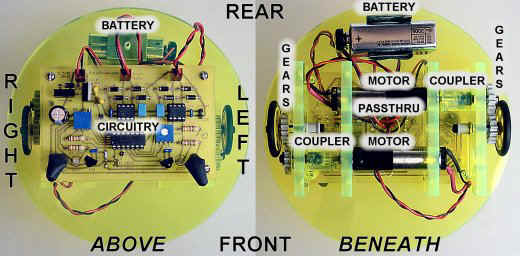

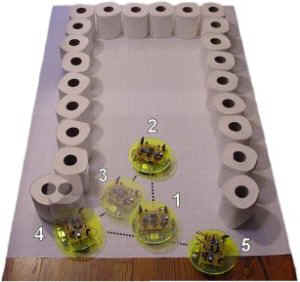

Chapter 13: Roundabout Robot

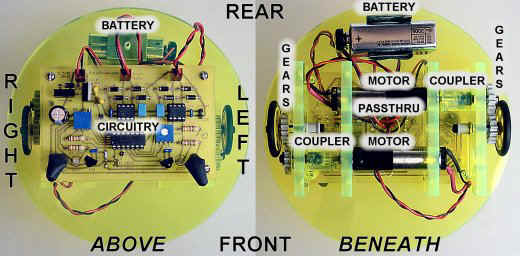

The electronic modules and machining techniques presented thus far in the book can be

connected together to make Roundabout, a room-exploring robot. Detailed photographs of

Roundabout are shown from all angles. The circuitry and motions are described.

The particulars of machining Roundabout's robot body are described in the second half of

this chapter, including tips on using templates, machining multiple pieces at the same

time, and two methods of targeting a drill. A compact method of mounting motors side by

side is shown, along with choices on gearing up, gearing down, and idle power train

transfer.

This chapter also provides a couple of suggestions for making slides for the robot, and

when not to make the robot slide. During the building of Roundabout, a couple of mistakes

are caught and described in this chapter.

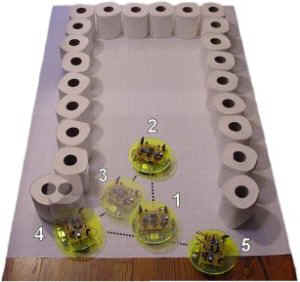

Chapter 14: Test Driving Roundabout

Before launching the robot, a series of tests are performed that are applicable to any

robot. These tests include a safe way to drain power and a simple way to measure current

usage.

The robot is then put through the paces. A low-tech approach to test-facility materials

reveals the robot is socially aware (okay, maybe not). Actually, a significant limitation

to having a brainless robot is discussed, along with why a round robot body may not be the

best shape.

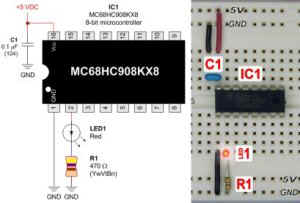

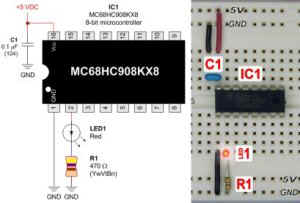

Chapter 15: Microcontrollers

This book does not focus on one brand of microcontroller over another. Although a

particular microcontroller, (the 68HC908KX8), had to be selected for the upgrade of

Roundabout, this chapter describes the various features available in 8-bit

microcontrollers in a generic way. Selection criteria and a few recommendations are made,

but the examples in the book are generalized for use with any microcontroller you prefer.

This chapter explains the benefits of a microcontroller over an off-the-shelf logic chip

(including a potential improvement to implementing an infrared reflector detector). It

then describes the steps that you might go about to program a microcontroller and test it,

including a simple heartbeat indicator.

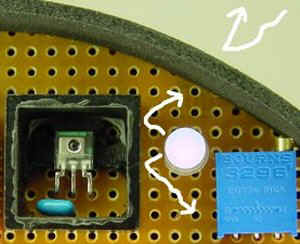

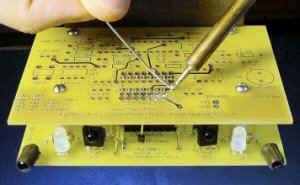

Chapter 16: Upgrading Roundabout with a Daughterboard

This chapter returns to working on Roundabout. In this case, upgrading the robot by adding

a microcontroller and other features. Ordinary 0.1" spaced boardmount sockets permit

the daughterboard to be snapped right on top of the motherboard. This technique is

applicable to any modular robot.

Also included in this chapter are tips on selecting machine screws, trimming and reheating

solder joints, screening out ambient lighting, debouncing inputs with both hardware and

software, and adding DIP switches.

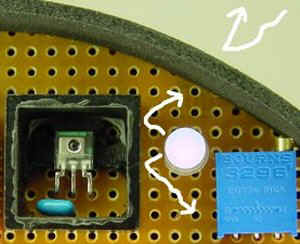

Chapter 17: Floor Sensor Module

This chapter explains the purpose of the wavy lines and gap size of CdS (cadmium-sulfide)

photocells / photoresistors and why you can't tell the resistance by its cover. Schematics

and breadboard examples show the common ways of connecting photoresistors in a circuit.

The first section of this chapter should hopefully dispel the myth that photoresistors

provide "near linear" responsiveness. The actual mathematical formulas and how

they relate to a particular photoresistor's sensitivity are explained.

Two major weaknesses of photoresistors are divulged: large manufacturing variance and very

slow responsiveness. After reading this chapter, you'll avoid CdS photocells in your next

line-following robot champion.

There is a wonderful alternative to CdS photoresistors, the light-to-voltage converter IC.

It's easy to hook up and is available to sense white light or various colors (red, green,

or blue). This part is employed in making a floor sensor board that connects to

Roundabout. The shades and baffles on the board are lightweight, fairly simple to make,

and definitely improve performance.

The chapter ends with algorithms for implementing line-following and robot sumo on either

Roundabout or any other robot with similar modules.

Chapter 18: Robot Stew

The last chapter is where all the leftovers go. Yet, the wide variety of subjects make

this one of the most interesting and easy-to-read chapters.

The chapter begins with an LM386 audio amplifier circuit and its implementation. It is

used along with a PWM (pulse-width modulator) pin on the microcontroller to play music as

the robot drives around. Besides being fun, musical tones are a good debugging tool,

especially for a robot that lacks a text display. A method for transcribing and

programming music is included.

The next portion of this chapter describes a roomy upgrade to Roundabout's body. It

includes Teflon roller slides, integrated wheel slots, and colorful homemade spacers. But,

best of all, are the instructions for making quick, dependable, accurate motor mounts.

Two other motor mounts and another type of motor-to-LEGO coupler are detailed. Then it's

on to comparing four types of sensors on a solar robot. Which do you think worked best:

photoresistor eyes, metal-whisker obstacle detectors, a front-contact bumper switch, or an

undercarriage contact switch?

Roundabout goes video! Here's a simple way to add telepresence to

your robot...

|

Chapter

1: Assembling a Modular Robot

Chapter

1: Assembling a Modular Robot